Contributor: Sam Kelton

Spherical valves are just one of the many types of valves working in high-pressure applications in reciprocating pumps. Many believe that valves are ‘equal’, regardless of type. While this is true in the sense that all valves allow or inhibit the flow of fluids, there are distinct differences that make some valves more preferable over others in certain applications. Let’s take a brief look at the most common types of valves used in reciprocating pumps – more specifically, the advantages and disadvantages of each type of valve.

The abrasion resistant or “AR” valve is “considered” to be the gold standard for general purpose use in reciprocating pumps. AR valves are constructed to clear debris from the valve in harsh pumping environments and, as the name suggests, highly resistant to the effects of adhesive wear, abrasive-corrosive wear, and crunching/grinding wear.

When the valve is supplied with a urethane insert as part of the valve member, the insert prevents metal to metal contact and significantly reduces abrasive wear, particularly in the presence of particulate matter common to mud/slurry and fracturing operations. AR valves are also a reasonable choice for use under service conditions in which suction pressure is adequate and where fluid temperatures tend to be 160°F or less (if using an AR valve with a polyurethane inserted valve member).

AR valves have a “crossed” valve member that extends through the bore of the seat to the bottom of the valve and typically have very light spring pressure. Due to the construction of the valve member, the available flow area (based on bore diameter) is reduced by approximately 15%. The light spring pressure means that valve closure delays can be expected at higher RPM, which have become common with acceptance of processing technologies that can produce higher volumes of material faster than their predecessors. This results in a slight reduction in the volume of fluid expelled from the pump chambers and less than the efficient operation of the pump overall. So by current standards, the AR valve fails as the gold standard for reciprocating pumps.

The Plate Valve

The plate valve, not to be confused with the extremely efficient and durable Durabla® valve, is another valve in common use in reciprocating pumps. The plate valve can be supplied with a polymer disk, typically Delrin®, which significantly reduces overall wear and can be used within the same temperature range as urethane. Unlike the AR valve, the plate valve utilizes a dual spring design which permits some customization of the valve for use in low and standard suction pressure systems as well as some high-speed systems.

Plate valves are usually stem-guided and can be used in pumps which require a valve with a lower profile than that of the AR valve. Rather than using a cage to contain the upper works of the valve, they have structural cross beams built into the seat to which the stem is secured in the center. The cross beam is located in the bore of the valve which reduces flow through the valve. Since the beams are structural, they are significantly larger than the cross pattern of the valve member of an AR valve of equivalent size.

So while equally abrasion resistant, more efficient, and significantly better in price than AR valves, the plate valve is susceptible to being held in the open position when encountering debris in harsh pumping conditions. It is also more restrictive to the flow of fluid and has a greater impact on a company’s bottom line long term.

The Ball & Cage Valve

Ball & Cage valves, when used, are most commonly seen in high temperature and high-pressure applications. Their construction is very basic, typically consisting of a seat with a radiused seating surface, a hardened metal ball, and a spring which applies a force to the ball in the direction of the seat.

The advantage the ball & cage valve has over the AR and plate valves is that over a fixed horizontal distance, the sealing surface of the ball & cage valve is greater. This allows for a smaller seating surface profile and a larger flow area without loss of sealing integrity. Additionally, the bore of the ball & cage valve is completely unrestricted which means fluid flows freely through them in proportion to the valve area.

However, due to the constant metal on metal contact, ball & cage valves tend to pit and corrode easily and require replacement more frequently than their AR and plate valve counterparts. Additionally, they are not particularly suitable for use in mud/slurry applications or in systems that move fluids containing large particles.

The Spherical Valve

Spherical valves are designed similar to ball & cage valves in regard to the radiused seating surface but without the bulk & weight of the entire metal ball. The spherical valve combines the strengths of the previous three valves types while reducing the number of disadvantages.

Spherical valves can have:

- the abrasion resistant qualities of an AR valve for use up to 500°F

- the versatility of a plate valve without the extreme restriction to flow

- the increased flow area and strong seal of a ball & cage valve without the susceptibility to abrasion

However, not all spherical valves are created equal. Some spherical valves in the market today utilize a retaining cage secured by bayonet style lugs. These lugs have a tendency to wear out over time causing the valve to come apart inside the pump. This can do serious damage to the pump’s fluid end. The second problem with these valves is a gap between the cage and seat where debris can build up, locking the valve cage in place. This makes it very difficult to almost impossible to disassemble the valve and extract it from the pump.

The WG Sphera™ Series Difference

The WG Sphera™ spherical valve is a cage-guided valve that uses:

- a radiused valve member that allows for a larger flow area, adequate sealing and unrestricted flow.

- inserts made from polyketone, PEEK or Teflon® to improve abrasion resistance and allows high-temperature operation.

- dual shot peen Inconel® springs which:

- reduce spring fatigue

- accommodate use in low pressure, high pressure, and high-speed pumping systems.

Here’s how the above characteristics work in the WG Sphera™ valve in comparison to the previous valve types:

The WG Sphera™ valve does not use a structural cross member and does not have an extended valve member; both of which tend to reduce flow. As with the ball & cage valve, the radiused mating surface of the WG Sphera™ valve allows for a larger flow area without loss of seal integrity. This results in an increase in net fluid through the valve of up to 44% which can have a positive impact on the volumetric efficiency of the associated pump and improved performance of the overall system.

When used with its unique Sustakon® insert, the WG Sphera™ valve provides corrosion resistance equivalent to that of the abrasion resistant and plate valves. The insert is available in a relatively wide selection of materials. Sustakon® is our default material, but the WG Sphera™ valve can be supplied with inserts made from PEEK, and Teflon® upon request.

The shot peen Inconel® springs resist fatigue and last longer than their 316 stainless steel counterparts. Variations in available suction pressure between systems or within a single system require a versatile valve that can be adjusted to suit the pressures that are available. While tuning a valve is still a significant engineering effort, the WG Sphera™ valve’s dual spring design allows it to be more closely matched to the available suction pressure simply by specifying 1 or both of 2 available springs. Here’s how it works:

- The smaller inner spring is light pressure (2 POSIVA) for low suction pressure systems. When used alone, the spring significantly reduces the cracking pressure of the valve allowing it to open properly in low NPSH systems. This reduces or even eliminates starvation of the pump and encourages normal operation when suction pressure is slightly less than recommended.

- The outer, heavier spring (4 POSIVA) is standard and recommended for systems with adequate suction pressure. Normal opening of the valve is maintained while valve closure is optimized which can reduce loss from the chamber between plunger rotations.

- The dual spring configuration is recommended for use only in high RPM systems or where lagging in valve closure is prominent.

Together, these improvements result in longer life and reduced maintenance cost over the life of the valve. Overall, the WG Sphera™ valve combines the benefits of the AR, plate and ball & cage valves without compounding their disadvantages.

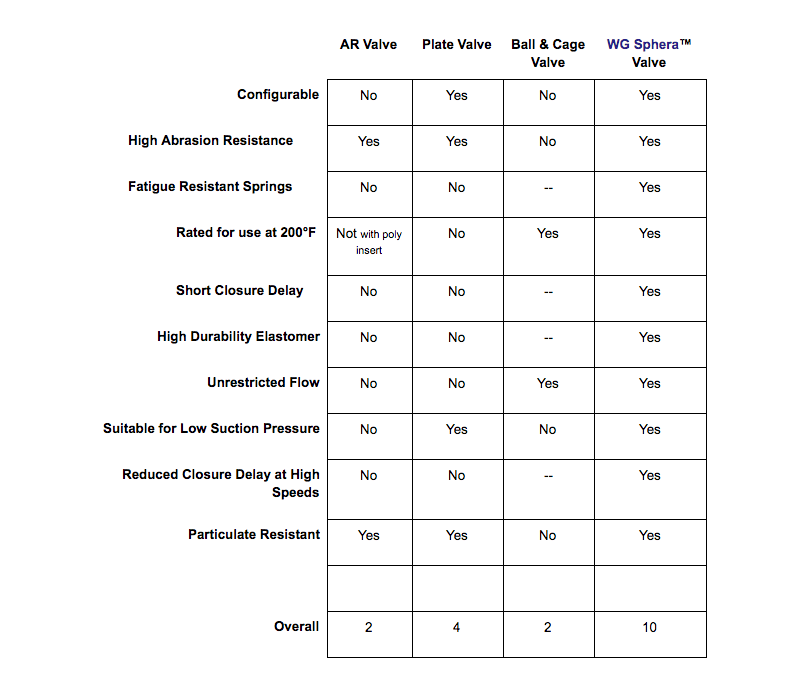

The following table compares some of the characteristics of the abrasion resistant, plate, and ball & cage valves against the WG Sphera™ series valve:

Conclusion

While it is fairly clear that there are advantages and disadvantages to choosing one valve over another, pumping system professionals continue to ask for the perfect balance between performance, price, and longevity of the equipment that they choose for their systems. Possibly, TPCI has answered that question for you today.

For 100 years, Triangle Pump Components Inc. has built a reputation for manufacturing efficient, long-lasting, and dependable pump products. This tradition of quality continues today throughout our entire product line. To find out how our products can improve your pump’s efficiency, contact us today.