Author: Chett Norton, C.E.T, Triangle Fluid Controls

The importance of plant operators and operations in water treatment facilities selecting the right gaskets cannot be overstated. Unfortunately, they are often the last thing that anyone thinks about, and are in most cases considered a commodity item. However, most operators say that it is gaskets that can cause the most “pain” on a day-to-day basis. This means that selecting the right ones is important for process safety, environmental protection, service life, and maintenance and inventory costs.

The National Sanitation Foundation (NSF) has created standards that are intended directly for drinking water and systems that treat and deliver it. NSF/ ANSI 61 standard is based on the health effects of drinking water components.

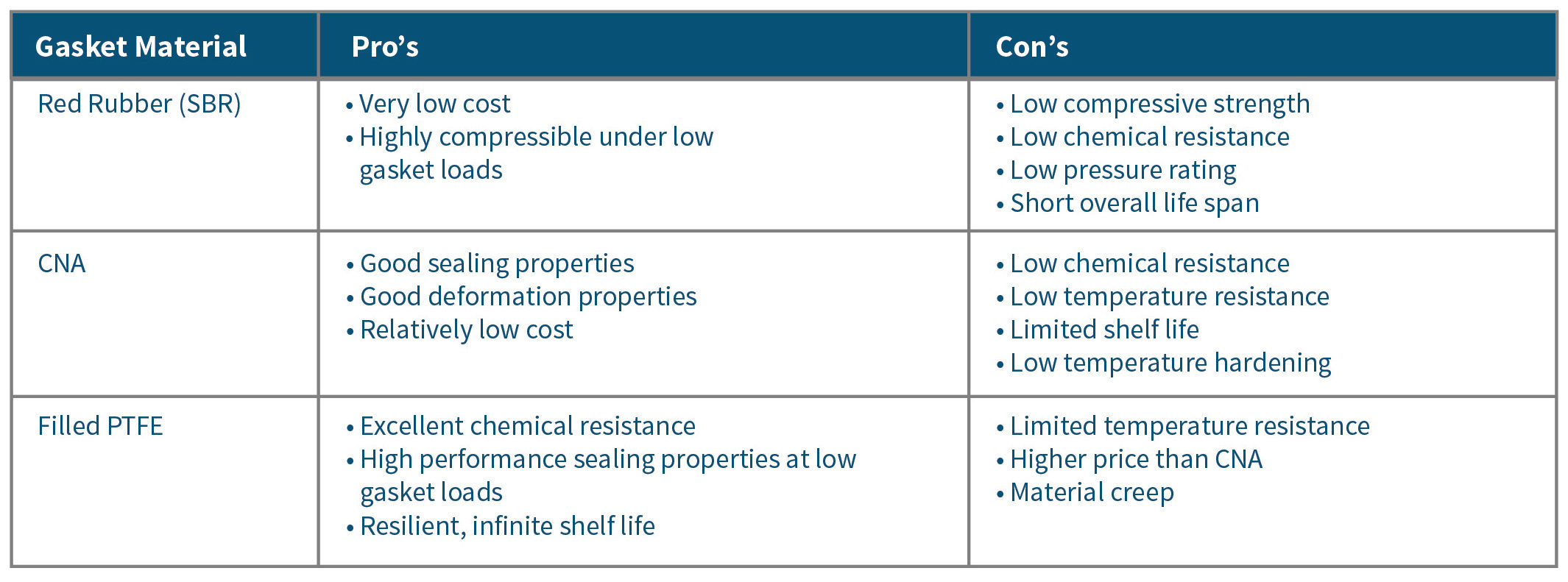

Unfortunately, municipal facilities do not always use NSF 61 approved gasket material. Red rubber, styrene butadiene rubber (SBR), is continually used for potable water applications. But, it is not an ideal gasket material because it is a pure elastomer which naturally degrades over time, because of natural environmental conditions. Red rubber also has a very low compressive strength, generally in the range of 800 psi – 1200 psi, which can result in the material crushing if these values are exceeded.

In most flange pipe connections, the amount of torque applied to the bolting to achieve a minimum bolt stretch of 40% may exceed these values. Failing to stretch the flange bolts to this minimum yield can be problematic because the bolting material is not within its elastic region, and cannot create a “spring like” clamping effect on the flanges. This can result in a leak, or perhaps a blow-out failure.

The chemical resistance of SBR is relatively low against common water treatment chemicals like sodium hypochlorite, caustics, chloramine and others. These chemicals can aggressively attack the red rubber, resulting in a rapidly degraded or deteriorated gasket. When the gasket is chemically attacked, it is susceptible to leaks, failures or perhaps even a gasket blow-out which can seriously harm plant personnel if they are sprayed with these chemicals.

For general plant services that process non-potable water, steam and various forms of waste products, compressed non-asbestos (CNA) gasket material is a good choice because of its good sealing characteristics, ease of cutting and relatively low cost.

CNA gasket material has three main components: fibre (15% – 35%), binder (10% – 20%), filler (50% – 70%). Additionally, there is a small percentage of vulcanizing chemicals which are usually solvent based and used to cure the rubber based binders during manufacturing. Fibre is added to the CNA gasket material to provide increased mechanical properties like tensile and compression, and can include aramid, cellulose, ceramic and glass. The binder is usually composed of an elastomer, namely nitrile, styrene butadiene rubber, or even ethylene propylene diene monomer rubber, which keeps the sheet bound and gives the gasket material added flexibility.

Fillers such as silica, mica, clay or even powdered graphite can be added to help control creep and reduce cold flow. Additionally, using fillers helps reduce the overall cost of the sheet because it consists of 50% – 70% of the total material. When selecting a CNA gasket material for potable water, the user should make sure they use a NSF 61 verified material to ensure that they are not contaminating the water source. Because CNA gasket material contains a rubber component, the material still does have a shelf life. Over time, the rubber will start to break down and deteriorate, based on exposure to environmental conditions.

Due to the rubber component of this type of gasket material, it is not recommended to seal applications that involve acids, or caustics which are used in pH control prior to the clarifying stages or even disinfection chemicals such as sodium hypochlorite (NaClO), 12% solution.

Even polymer-based chemicals used in wastewater treatment, including flocculants, coagulants and defoamers, can cause deterioration in rubber-based gasket materials. Therefore, it is very important to test the chemical resistance of the gasket material used with each chemical and to measure the concentration.

For critical service and chemical applications, filled polytetrafluoroethylene (PTFE) gasket material is an excellent choice because of its in-service longevity, chemical resistance and high sealability.

PTFE has an infinite shelf life; therefore, it does not break down during exposure to environmental conditions. This makes it a superior choice for applications that are not easily accessible or perhaps buried underground. PTFE is also inert to almost every chemical, making it a great choice for chemical applications.

Pure virgin PTFE has high creep/relaxation characteristics, so it is not a good sealing material. To help prevent material creep, gasket manufacturers use engineered filler systems that can consist of glass, barium sulfate and/or carbon.

Filled PTFE seals at a much lower gasket stress than compressed non-asbestos products. However, it can also withstand loads of up to 15,000 psi, which is more than 10 times the compressive strength of red rubber. 75 mm, 200 mm and 300 mm 150# ANSI flanges can be problematic to seal due to the low cross-sectional “bolt area” to gasket “sealing area” ratio. Full face gaskets are also difficult to seal when compared to ring gaskets, due to having two to three times more sealing area. For these applications, filled PTFE is a preferred sealing material.

Full face flanges are generally found on pumps and cast iron 125/250# piping. In many cases, you cannot generate enough gasket compression stress to create an effective seal without damaging the flanges. For these flat face flange applications, reducing the gasket area will help increase the gasket stress. When bolting up the gasket, a reduced contact area gasket made up of filled PTFE, will allow the full face skeleton design to support the entire flat face flange. It will also prevent any damage that may be caused by bending or flange rotation if a ring gasket were to be used.

The application will influence the gasket selection; however, proper gasket installation is equally important. Based on 100 gaskets analyzed and material collected from the members of the Fluid Sealing Association, up to 85% of gasket failures were due to faulty user installation. Sixty-eight percent of the gaskets failed due to under compression, while 14% failed due to over compression.

It should be noted that both under and over compression of the gasket can be prevented if installers use a proper tightening method, recommended torque value and a calibrated torque wrench or other tightening device. For proper gasket installation methods, users can reference the ASME PCC-1 post construction guideline for pressure boundary bolted flange joint assembly. Gasket manufacturers provide recommended torque values and installation procedures.

https://empoweringpumps.com/white-papers/triangle-fluid-controls-gasketing-bolt-tightening-worksheet/